WoodenuKnow.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com and may earn from qualifying purchases.

A workbench is an important tool for any handyman, but it’s not very useful if the finish isn’t right. It might be tempting to just paint it and call it good, but that won’t last. You should finish your workbench to make sure that it will survive.

A good finish for a workbench can protect it from scratches, unwanted yellowing or darkening, moisture, and abrasion. It can also help keep glue, paint, and other gunk from sticking to the workbench top.

Workbenches are available in many different finishes, so deciding which is the best finish for workbench can be confusing. Luckily, we have a solution for you.

In this article we’ll talk about the top 8 finish protects for workbench and how to choose one that’s right for your needs. We’ll also discuss brief explanations of related information that can help you make an informed decision.

8 Best Finish for Workbench Reviews

A workbench is a type of bench that is generally used by carpenters, metalworkers, woodworkers, or other similar craftsmen while constructing a table, a fixture, or any other kind of furniture in a workshop.

Workbench finishes are important because they determine how well your tools and materials will remain in place, and how easily they can be accessed when needed. The followings are our top 8 picks for workbench finishes:

1. Rust-Oleum Smooth Finish for Workbench

The Rust-Oleum finish is a matte clear top coat that creates a rustic, beautiful look on workbench surfaces for any workshop. It is also extremely durable, so you can rest assured your workbench will be both attractive and sturdy.

This type of finish easily creates a vintage look, which can be great for adding character to your workspace. Plus, it’s also easy to use, making it a perfect choice for anyone who wants the perfect finishing touch for their workbench.

With its low-odor/VOC formula, this product is easy to clean up. For those who want an easy way to clean up their workbench, this is an excellent choice. Non-toxic, it is safe for those who wish to avoid harsh chemicals.

This Rust-Oleum Smooth Finish for Work Bench provides easy one-coat coverage, which allows projects to be completed quickly and easily. The dry time is just 30 minutes, so you can get started on your project right away.

It’s easy to apply, and requires little prep work, making it a great choice for busy professionals or DIY enthusiasts. Plus, the excellent adhesion ensures a durable finish that won’t let you down.

A workbench would have this finish, which would dry ultra-matt, velvety and smooth. This would provide a protective layer that would keep the workbench looking new while also being highly functional.

Highlighted Features:

- Creates a rustic, vintage look

- Dries smooth and ultra-matt for a protective finish

- Provides excellent adhesion and one-coat coverage

- Comes in a low-odor/VOC formula for easy cleanup and safety

- Creates a workbench that is both attractive and sturdy

- Provides 30 minutes of dry time

- Comes in a 30.0 Fl Oz can for more convenience

2. Howard FW0016 Newly Restored Wood Finish for Work Bench

Howard finishes are excellent for use on wooden furniture and floors. It leaves a nice shine and prevents scratches and other damage. You can use this product on any bare wood furniture or floor to keep it looking new and shiny.

The Howard Newly Restored Wooden Finish for Work Bench is a must-have for people who want to preserve wooden surfaces. Providing a durable layer of protection, the Carnauba Wax and Beeswax formula buffs to a beautiful luster.

If you’re looking for a high-quality workbench that’s made in the USA, then you should consider this one from Howard. It features a beautiful wooden finish and comes with a conditioning oil that helps to keep the wood looking great.

Howard’s FW0016 for the workbench is a great way to enhance the natural beauty and depth of grain in unfinished or finished wood. It dries quickly and leaves a smooth, hard finish that’s free of unsightly surface marks or streaks.

The Howard finish for the workbench can be used on a variety of surfaces, including antiques, kitchen cabinets, dining tables, and wood doors and trim. It provides a tough, high-gloss finish that is both beautiful and easy to maintain.

Following Restor-A-Finish on the workbench, it is the ideal product to use. It helps to prevent further drying of the wood and deterioration of the finish. As it contains no silicone or linseed oil, it won’t interfere with the original finish.

Highlighted Features:

- Carnauba wax and beeswax formula

- Keeps wood looking new and shiny

- High-gloss finish that’s easy to maintain

- No silicone or linseed oil-based finish that quick-drying

- Perfect for unfinished or finished wood surfaces

- Helps prevent the finish from further drying and deteriorating

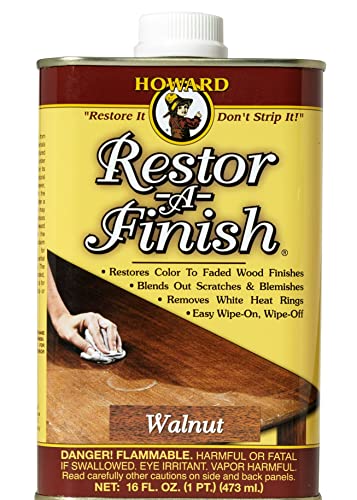

3. Howards Restor a Finish for Work Bench (RF4016 RF3016)

Howard Restor-A-Finish is a unique product that can be used to restore the finish on wood furniture and other wooden objects. It comes in walnut color and can be used to either match or contrast the color of the wood.

Restor-A-Finish may be the perfect product for you if you’re looking to restore your wood surface as well as blend out minor scratches and blemishes. Whether your furniture is old or new, Restor-A-Finish can bring it back to life.

It’s always a shame to see a nice piece of wood go to waste just because it’s starting to look a little bit rough. But with Howards Restor a Finish for Work Bench, you don’t have to worry about that anymore!

In a few minutes, you can restore most finished wood surfaces with a simple wipe-on, wipe-off procedure. In other words, if you’re looking for a simple way to upgrade your old workbench, this is it for you.

Howard’s furniture finish does miracles when it comes to restoring furniture to its former glory. This finish is great for removing white heat rings and watermarks, sun fade, smoke damage, oxidation, and any other blemishes!

The workbench could be restored by using a stain that is the same color as the original finish. This would help to cover up the areas where the finish has been stripped, and it would also make the workbench look nicer.

Highlighted Features:

- Restores the natural color of wood

- Compatible with most types of wood

- Easy to apply, easy to wipe off

- Doesn’t cause any unwanted yellowing or darkening

- Improves gloss and adds shine to the wood

- Enhances and deepens the wood color

4. Minwax Helmsman Spar Urethane Finish for Work Bench

Minwax 33255000 finish is a great option for finishing wooden workbenches. The satin finish provides durability and resistance to scratches and abrasion. It dries quickly, so you can get back to work immediately after applying it.

The Minwax Helmsman Spar Urethane Finish for Work Bench is a protective coating that not only contains UV blockers. As well as reducing the sun’s fading and graying effects, it also provides a tough, durable finish.

This satin finish can be used on both indoor and outdoor projects and is available in a variety of colors to match your decor. Minwax is a finish that you can use to protect your workbench from rain and moisture.

The product protects your workbench from scratches, water damage, and other wear and tear. It is made of special oils that allow it to expand and contract with the wood as the seasons and temperatures change.

Spar urethane is a tough, fortified alkyd resin that is designed to dry hard without being brittle. A variety of wood species can be treated with the product, and it can also be applied over existing finishes.

A durable, weather-resistant finish like this is perfect for protecting patio furniture, bar tops, exterior doors, window sills, and wooden boats. This product is excellent for wood surfaces as it resists chipping, checking, and cracking.

Highlighted Features:

- Suitable for interior and exterior projects

- Expands and contracts with wood for a perfect fit

- Resists finish for superior protection

- Provides a tough, durable finish

- Quick-drying and easy to use

- Helps protect from moisture and abrasion

5. Incredible Solutions High Gloss Finish for Work Bench

Incredible Solutions epoxy is perfect for finishing your workbench. With a high gloss and UV-resistant coating, it will protect your bench and keep it looking great for years. It self-levels for a quick and easy application.

The custom epoxy formulation allows for minimal bubbles, helps eliminate fish eyes, goes on smooth, craters, and various other imperfections. This High Gloss Finish for Work Bench has an easy mixing process and a glossy acrylic coat.

It is also water and impact-resistant, making it ideal for use in high-traffic areas. Additionally, epoxy resin auto-levels on application, making it easy to apply even in difficult areas like corners and along bar rails and live edges.

USA Factory’s Incredible Solutions finish for the workbench is a great choice if you’re looking for an epoxy that is low-odor and mixes well with pigment powders. It cures crystal clear, so you’ll get the look you want with no problem.

It is a 1:1 mixture that covers 12 square feet at 1/8 inches thick. Despite its rock-hard consistency, this mix can be used in numerous applications.

There are many things you can repair with this product, including tables, countertops, and even floors. In addition to being stain and scratch-resistant, it is also a great choice for repairs as it is easy to maintain.

Highlighted Features:

- Protects and adds value to all kinds of furniture and fixtures

- Quick and easy to apply with a 1:1 mix ratio

- Self-leveling can be applied in difficult areas

- High gloss finish for protection and aesthetics

- Cures clear, making it ideal for use in high traffic areas

- The thickness of 1/8 inches can be achieved in 12 square feet

6. Hope’s Waterproof Natural Wood Finish for Work Bench

Hope’s wood sealer and finish that is designed to waterproof and protect your woodworking projects. The oil-based finish is non-toxic, making it a safe choice for use around children and pets, and it dries quickly to provide a durable finish.

Tung oil is a great finish for woodworking projects. Hope’s Waterproof Natural Wooden Finish for Work Bench is easy to use and gives a beautiful, hand-rubbed finish. Just wipe it on and let it cure at room temperature.

Other finishes form a film on the surface of the wood, but tung oil penetrates deeply into the wood fibers, cures into a flexible, non-oily solid, and becomes an essential part of the wood itself. The result is a finish that looks great and is sturdy.

It is resistant to moisture, oil, alcohol, and everyday wear, which means it keeps your workbench looking beautiful. In comparison to wax-based and oil-based finish products, this finish will be more enduring.

Surfaces can be protected and enhanced with Hope’s Finish. It can be applied to new, unfinished wood to help it retain its natural color and texture, or it can be used on weathered, stripped, or concrete surfaces to give them a new look.

Tung oil-based finish is derived from the nut of the tung tree, and it’s known for its durability and resistance to alcoholic drinks. Plus, it’s non-toxic when dry, so it’s perfect for use on cutting boards, countertops, butcher blocks, wooden bowls, and more.

Highlighted Features:

- Formulated with natural ingredients

- Safe and non-toxic on food surfaces

- Waterproof and stain-resistant

- Dries quickly for a durable finish

- Penetrates deep into the wood to enhance the grain

- No film or forming, so it won’t peel off the surface

7. Rust-Oleum 260165 Protective Matte Finish for Work Bench

Rust-Oleum 260165 polyurethane finish is a matte type that can be used on workbenches. This product is fast drying and easy to apply, making it a great choice for any DIY project.

This product is perfect for protecting interior wood surfaces from wear and tear. Whether you’re working on cabinets, doors, trim, or any other wood surface, this Protective Matte Finish for Work Bench is the perfect way to protect it.

If you’re looking for a topcoat that will provide excellent scratch and stain resistance, Rust-Oleum’s polyurethane finish is a great option. The finish is soft and smooth, making it a great choice for any workbench.

Rust-Oleum’s water-based acrylic finish dries quickly and cleans up with soap and water. Whether you’re a professional woodworker or just DIY-ing in your garage, this product is sure to help you get the job done right.

When it comes to finishes and coatings, Rust-Oleum is a trusted brand. A durable finish is provided by this product, which dries within an hour. It also covers up to 150 sq. ft. per quart, making it a great option for larger projects.

Rust-Oleum’s matte polyurethane finish is perfect for workbenches as it reduces the appearance of fingerprints and smudges. This makes it easier to keep your workbench clean and looking professional.

Highlighted Features:

- Durable protection for indoor wood surfaces

- Water-based acrylic formula

- Cleans up with soap and water

- Covers up to 150 sq. ft/quart

- Perfect for use on cabinets, doors, trim, or any other wood surface

- The matte finish makes it easier to keep your workbench clean

- Reduces the appearance of fingerprints and smudges

8. Tried & True Premium Wood Finish for Work Bench

This tried and true woodgrain finish is an excellent way to protect your workbench from wear and tear. It provides a hard, durable finish that will keep your workbench looking new like the first day you built it!

Tried & True Premium workbench finish is safe for both skin contact and for use in food preparation areas. Any workbench will benefit from its toughness and durability. In addition to its simplicity, it is also easy to clean.

Despite being an environmentally friendly and safe option, it is also free of dyes, solvents, petrochemicals, and VOCs.

These two finishes are ideal for a workbench from this product: polymerized linseed oil and beeswax. Moreover, they provide a beautiful soft matte finish that not only protects the wood from moisture but also enhances its beauty.

All Tried & True products are made with ingredients from renewable sources like trees, bees, and seeds. Because of their renewable nature, they can be used for all types of projects around your home, from furniture to flooring.

The coverage rate is 1000 sq ft per gallon, meaning that it provides a lot of coverage for a while. It’s linseed oil also very easy to apply the finish, so you will be able to get the protection you need quickly.

Highlighted Features:

- Provides a beautiful soft matte finish

- Protects the wood from moisture

- Environmentally friendly and safe

- No dyes, solvents, petrochemicals, or VOCs

- Made from renewable sources like trees, bees, and seeds

- The coverage rate is 1000 sq ft per gallon

These are our top picks when it comes to the best finish for the workbench. While there are plenty of other options on the market, these finishes will help you get the results you want for your project.

How to Choose the Best Finish for Workbench?

Choosing a finish can be a time-consuming process, but it is an important part of the project. You need to take the right kind of finish to match your specific needs. Thus, the following factors can help you determine which one is right for your workbench.

Purpose

Knowing exactly what you want to use it for is an important first step in choosing the right final for your workbench.

Some finishes simply provide protection and a nice smooth look. While others can provide additional benefits such as insulation, waterproofing, or long-term durability.

Material

As you might imagine, not all finishes work the same way. Some specific types of finishes are better for certain types of materials.

For example, epoxy is great for concrete surfaces while polyurethane finish, water-based is perfect for wood. Thus, it’s important to know what sort of materials your project includes so that you can choose the right one.

Coverage Rate

Every finish will have a specific coverage rate, which tells you how much it can cover in terms of surface area or volume.

For instance, some finishes may be able to cover 50 sq ft per gallon while others are only able to do 10. The coverage rate will vary depending on the product you use.

Durability

Durability is a critical factor when choosing a finish for your workbench. You want to make sure that the finish you choose will survive as long as possible, especially if you plan on using it regularly.

Different finishes have different durability rates, so find something that will not wear down quickly from use or other factors.

Application Method

The application method is the last factor that you should take into consideration.

Different finishes can be applied in different ways, some requiring special tools or skills to complete the job correctly. Make sure you know what your skill and tool level are before choosing a finish for your project.

Also, consider how much time you have to complete the project. Some finishes may require multiple coats or special tooling that can lengthen the job, so find something with minimal application requirements if possible.

Drying and Curing Time

Some finishes might take days to fully cure, while others are ready in a matter of hours or minutes. If you are planning on using the finished workbench soon after applying it, make sure you know how long before you can start working on it again.

Also, take into consideration how long it takes for the finish to dry completely. If you plan on applying multiple coats of one finish, you might find that some cure too slowly and affect the appearance of the final coat.

Ease of Use

Some finishes are much easier to apply than others, which can make a big difference in terms of your overall project time and effort.

Understanding how easy it is to use the finish you choose will help you determine whether it’s right for this project or not.

Environment Friendly

While finishes are made to protect your workbench, they also come with their own environmental impact. Some are much better for the environment than others, which can make a big difference depending on where you will be using it.

If you want something eco-friendly that is safe for both you and the environment, then you should look for products that are free of toxic chemicals like dyes and solvents, as well as VOCs.

Finishing your workbench is a great way to protect it from the elements and make sure it looks nice and professional. Knowing a little bit about the benefits of different finishes will help you decide which one is right for this project.

As you can see, there are many different factors that go into choosing the best finish for your workbench. By knowing what each option offers and how to apply it, you will be able to determine which one is right for this project.

Type of Finish Coat for Workbench

There are various types of finishes to choose from when you are working on your workbench. Each one brings something unique to the surface, so take a look at the following examples before making your final decision.

Water Finish

One of the most popular options is water-based finish coats, which usually come in either oil-based finish or latex varieties. Oil-based finishes can be applied with a normal brush or roller for faster application.

Oil Finish

An oil-based finish offers more coverage per coat, although it is slower to dry. You will need to apply several coats in order to get the desired appearance, which can take some time.

Tung Oil Finish

Tung oil-based coats are popular with many furniture makers because of their ability to penetrate the wood beneath them. This allows for superior coverage, although you will need to apply several coats in order to reach your desired level of appearance.

Latex Finish

Latex finishes are very easy to use and won’t leave any brush strokes when applied correctly, but there are only a few types that are available for workbench projects.

Polyurethane Finish

Another common option is polyurethane finish, which comes in both oil and water varieties. The polyurethane varnish dries quickly and doesn’t leave brush strokes when applied correctly, but there are a few things to keep in mind before applying it.

Wax Finish

A wax finish coats the surface with beeswax or other types of natural wax, which is very smooth and easy to apply. Wax finish is also one of the most durable options for workbench projects but can take some time to apply correctly.

Now that you know more about these products, it’s time to start looking for one that matches your specific needs and project materials.

How Do You Finish a Wood Workbench Top?

When you use a finish coat for a workbench, you can use it in many different ways. Depending on the type of finish you choose and how it’s used, there are some steps that you should make sure to follow.

Step 01: Use the Right Tools

You should never start this project without making sure that you have all of the tools necessary. This includes using things like drop cloths, brushes, rollers, and different types of sandpaper to get the results you are looking for.

Step 02: Prepare Your Surface

Before applying any finish coat for the workbench you need to make sure that your surface is already ready for it. You can do this by applying a light coat of sandpaper to the whole surface, which will remove any rough parts and ensure that everything is even.

Step 03: Apply Your First Layer

After preparing the area you should begin applying your first layer of finish. Start with using an inexpensive roller to get the coat on smoothly. Make sure it is even, or else you will have problems with your project later on.

Step 04: Let It Dry

Before adding any more coats of finish coat for a workbench, make sure that it has dried completely. This will help prevent lumps and bumps from appearing as you continue to apply coats. It’s a good idea to check on it after an hour of letting it dry, just to make sure.

Step 05: Apply Your Secon Layer If Needed

After your first layer has dried completely, you can go ahead and add any second layers of finish that you may need. This will ensure that the surface is smooth even before completing your project.

Step 06: Let it Dry Again

You should always let each layer dry before adding another one and the workbench coat is no different. Make sure that it is completely dry and free of any dampness or moisture before applying another layer.

Step 07: Clean Up

After you are finished with your workbench then it’s time to clean up. Dispose of any unused material, including soft cloth and plastic gloves that have been worn during the project.

Be sure to take care of these things before starting another project. Otherwise, you risk contaminating your project with dust or other things that are harmful to your finish coat for the workbench.

Frequently Asked Questions

There are many questions that often arise when it comes to using a finish coat for the workbench. Here are a few of the most common ones:

1. Should I Finish My Workbench Top?

YES. Finishing a workbench that is made of wood serves two main purposes. Firstly, it’s an important part of protecting the surface from moisture and other things that can damage it over time.

Secondly, a finish coat for the workbench often results in a more attractive product that you can be proud to use or show off to others.

2. Should I Wax Workbench?

NO. A Wax finish coat for the wooden workbench is not typically recommended. This is because paste wax finish often becomes a sticky mess when in contact with water or other things that can make it dangerous to use in a workshop.

3. How to Finish a Plywood Workbench Top?

When you’re using a finish coat for a woodworking bench on plywood, the steps are pretty much easier. First, you should sand and clean the surface and apply a coat of wood primer.

Next, apply two to three coats of finish that match the color of your new choice or existing finish, allowing it to dry finely between each one.

4. How Often Should I Finish Workbench?

You should always check your workbench regularly for any imperfections such as chips, cracks, or anything else that might damage your finish coat. If you notice anything then it’s time to apply another layer of finish to protect the surface.

5. Is Boiled Linseed Oil Good for Exterior Wood?

Boiled linseed oil is a great way to protect the wood from the sun and rain like danish oil. It makes the wood look beautiful and helps to keep it in good condition. After you apply it, you need to wait for it to dry completely before using the material.

Conclusion

A finish coat for the workbench is a crucial part of protecting the surface from moisture, dust, and other things that can damage it over time.

Your workbench can be made as durable and protected as possible with the best finish for workbench. It can also make your workbench look aesthetically pleasing and give it a polished look that you will be proud to use or show off to others.

Now that you know what to look for in a workbench finish, be sure to check out our other articles on wood stains and paint! Thanks for reading! We hope we’ve inspired you to change your workbench based on your personal preference.

Possibly a Good Match: